Against the backdrop of the "1+N" policy system for achieving carbon peak and carbon neutrality, enterprises across the textile and apparel industry have been continuously undertaking low-carbon transformation across the entire product lifecycle. From a cotton bud, fibers, yarns, and greige fabric, to finished garments, textile and apparel companies have found that reducing carbon footprint from the source (raw material procurement end) is relatively easy to achieve and yields significant results.

Therefore, in recent years, textile and apparel enterprises have generally strengthened the use of green raw materials, aiming to reduce product carbon footprint. One such material, known as "zero carbon fiber," has emerged from the realm of green materials.

01 Green Development, Leading with Materials

In the textile and apparel industry, common environmentally friendly textile materials include natural fiber materials (such as cotton, flax, wool, and silk), regenerated fiber materials (such as viscose fiber, viscose filament, and lyocell fiber), and biodegradable materials (such as natural biodegradable materials, regenerated biodegradable materials, and synthetic biodegradable materials).

What was the precursor to zero carbon fiber?

Lyocell fiber [1], introduced in the mid-1990s, is a green fiber made from natural plant fibers, possessing a variety of excellent properties of both natural and synthetic fibers. It has been hailed as the most valuable product in the history of man-made fibers for nearly half a century.

How does Lyocell fiber become zero carbon fiber?

The raw material for Lyocell fiber is cellulose, an inexhaustible resource in nature. Cellulose is the most widely distributed and abundant polysaccharide in nature, accounting for more than 50% of the carbon content in the plant kingdom. It is derived from various sources such as wood, cotton, cotton linters, straw, rice straw, reeds, and hemp.

The chemical formula of cellulose

The chemical formula of cellulose

Building upon this foundation, zero carbon fiber was born. In 2020, the Lenzing Group developed the world's first "zero carbon fiber", which includes lyocell fiber and modal fiber. They also registered the trademark TENCEL™ for this product line. Subsequently, they have been expanding the zero carbon fiber product series.

Source: 2024 Lyocell Fiber Application Trend Report

It's worth mentioning that TENCEL™ is a trademark of the Lenzing Group. Essentially, the raw material is still lyocell fiber. Due to the high visibility of the Lenzing Group's TENCEL™ brand, there is a situation where the trademark is commonly used to refer to this type of product. In other words, many people use TENCEL™ to refer to lyocell fiber in their daily lives.

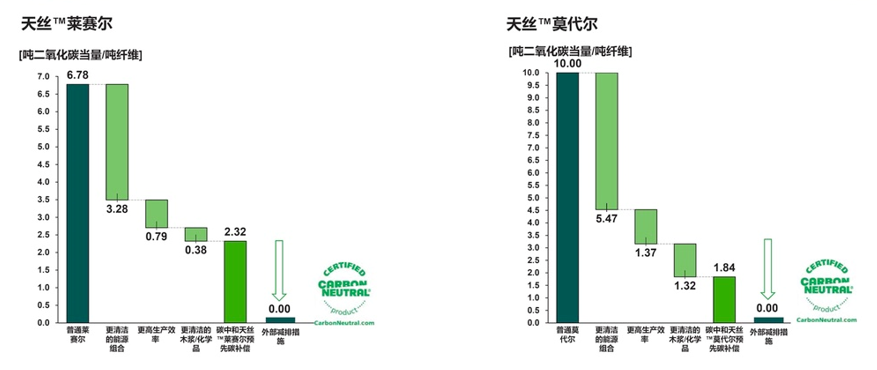

So how does lyocell fiber achieve zero carbon? Let's take the example of the Lenzing Group to explain.

The Zero Carbon TENCEL™ Fiber is certified by Carbon Neutral organizations

The Lenzing Group has established a "Reduce, Participate, Offset" trilogy. "Reduce" refers to reducing carbon emissions from a technical perspective at the source. "Participate" involves seeking like-minded environmental partners. "Offset" refers to participating in carbon reduction projects to offset carbon emissions that cannot be reduced during the production process. Ultimately, they have developed TENCEL™ fibers with net zero carbon footprint.

The carbon emissions of Lenzing's zero carbon products

In July 2022, Sateri, another leading fiber producer in the industry, launched three zero carbon fiber products. They are EcoCosy® by Sateri, Sateri Lyocell, and FINEX™ by Xinxiang Xinfengming Group. All three products have been awarded the PAS2060 commitment carbon neutrality declaration certification by SGS.

Sateri's carbon neutrality declaration certification statement

So far, zero carbon fibers are becoming increasingly well-known among downstream and midstream industry chain enterprises. According to the 2024 Lyocell Fiber Application Trend Report, in the full year of 2023, the annual production of domestic lyocell short fibers exceeded 300,000 tons, with an apparent demand growth of over 100%. The industry scale has gradually evolved from being "small and refined" to becoming a mainstream synthetic fiber product.

02 Zero carbon fibers: The new favorite of downstream brand manufacturers

Due to the lower carbon emissions of zero carbon fibers compared to traditional fibers, downstream brand manufacturers can reduce their carbon footprint from the source. Therefore, downstream brand manufacturers increasingly prefer to choose zero carbon fiber raw material suppliers. On the one hand, zero carbon materials align with the global trend of green and low-carbon development. On the other hand, they provide differentiated "selling points" and value growth points for products, meeting consumers' demand for green consumption.

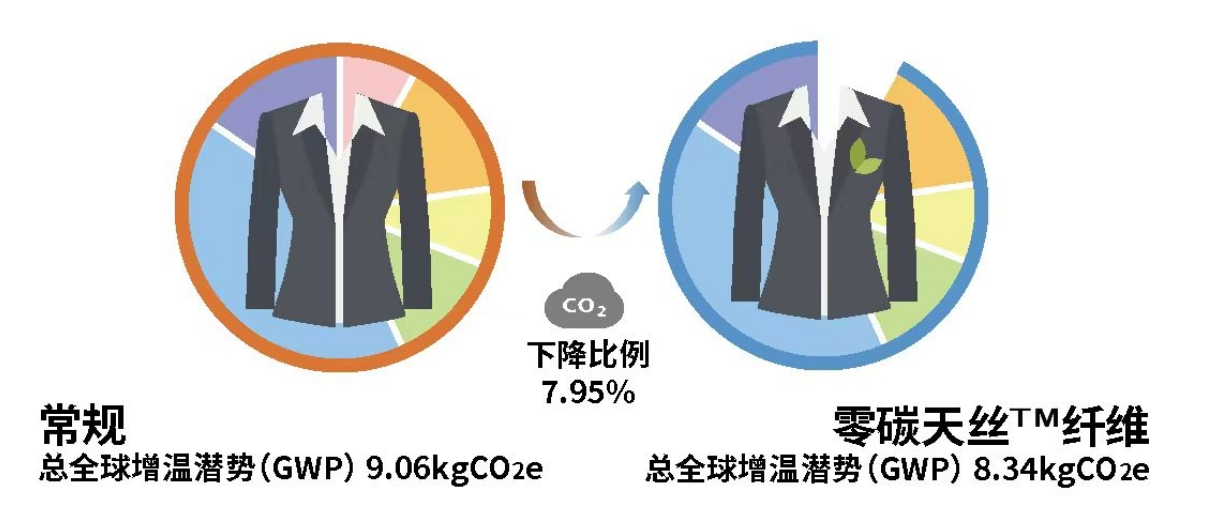

Eifini is a multi-brand lifestyle fashion retail group that pursues the ultimate pursuit of green sustainable fashion. It has collaborated with suppliers to develop zero carbon lyocell products and calculate the carbon footprint of the entire lifecycle of clothing. According to calculations, the suit made with zero carbon TENCEL™ fiber will reduce its total carbon footprint from 9.06kg CO2e per piece to 8.34kg CO2e per piece, resulting in a 7.95% reduction in carbon dioxide emissions.

Source: Eifini Women's Suit Carbon Footprint Brief Report

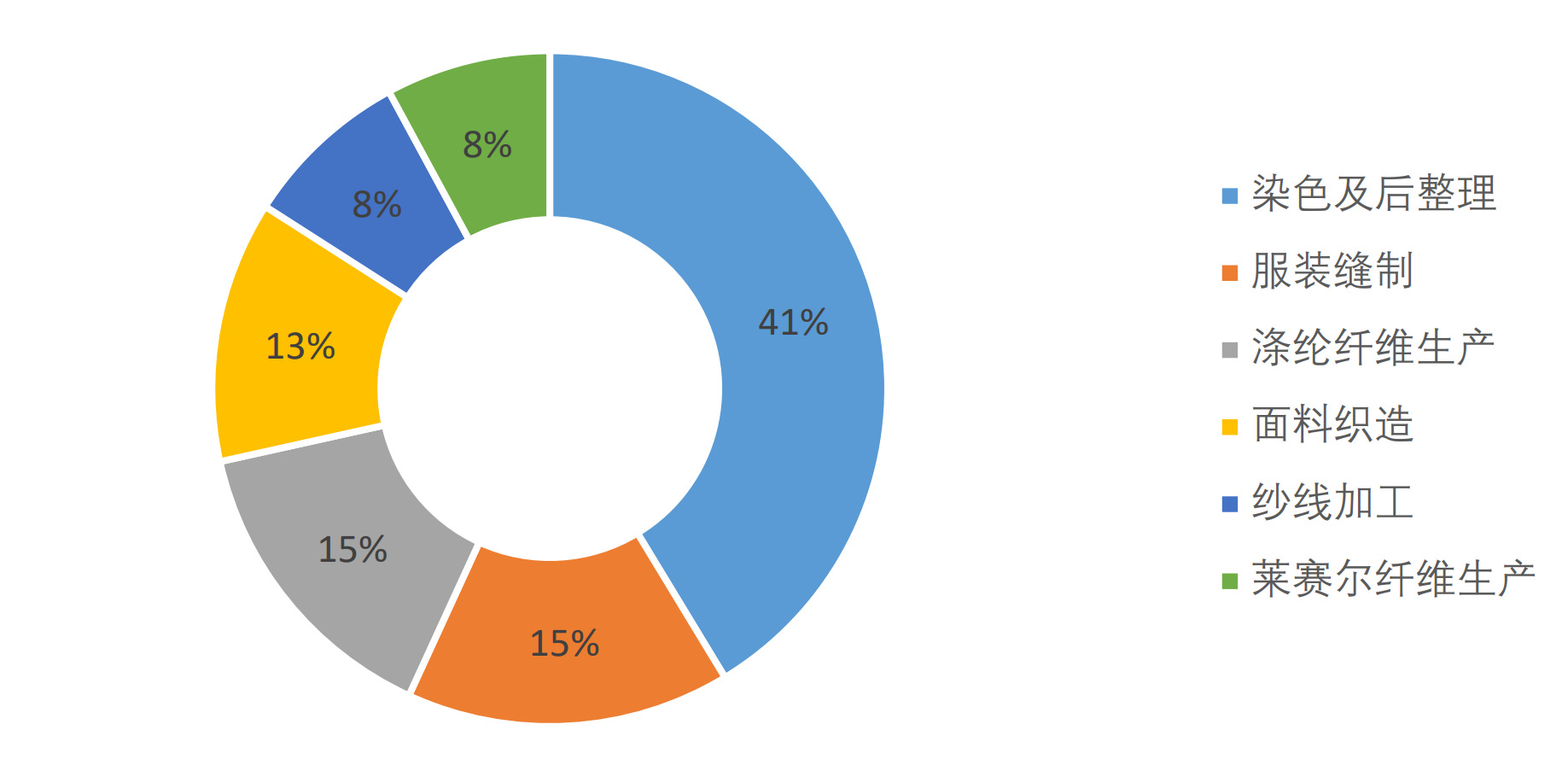

Through the carbon footprint report, the carbon emissions data for each stage are ranked as follows: dyeing and finishing (3.745kg CO2e) > garment sewing (1.407kg CO2e) > polyester fiber production (1.331kg CO2e) > fabric weaving (1.136kg CO2e) > yarn processing (0.728kg CO2e) > lyocell fiber production (0.716kg CO2e).

Carbon emissions at each stage of the Eifini women's suit

The zero carbon TENCEL™ underwear series developed by the well-known brand Hotwind, the carbon-neutral underwear series developed by Jiaona, the zero carbon TENCEL™ underwear series developed by Youkeshu, and the zero carbon products developed by Aimu children's wear all use TENCEL™ (zero carbon fiber) from the Lenzing Group.

Source: hot wind

In addition, textile and apparel brands such as Semir, Peacebird, LeTing, HeyBetter, and Fenteng have all used Lyocell fiber (zero carbon fiber) from Sateri to develop new products.

Semir's low carbon jeans

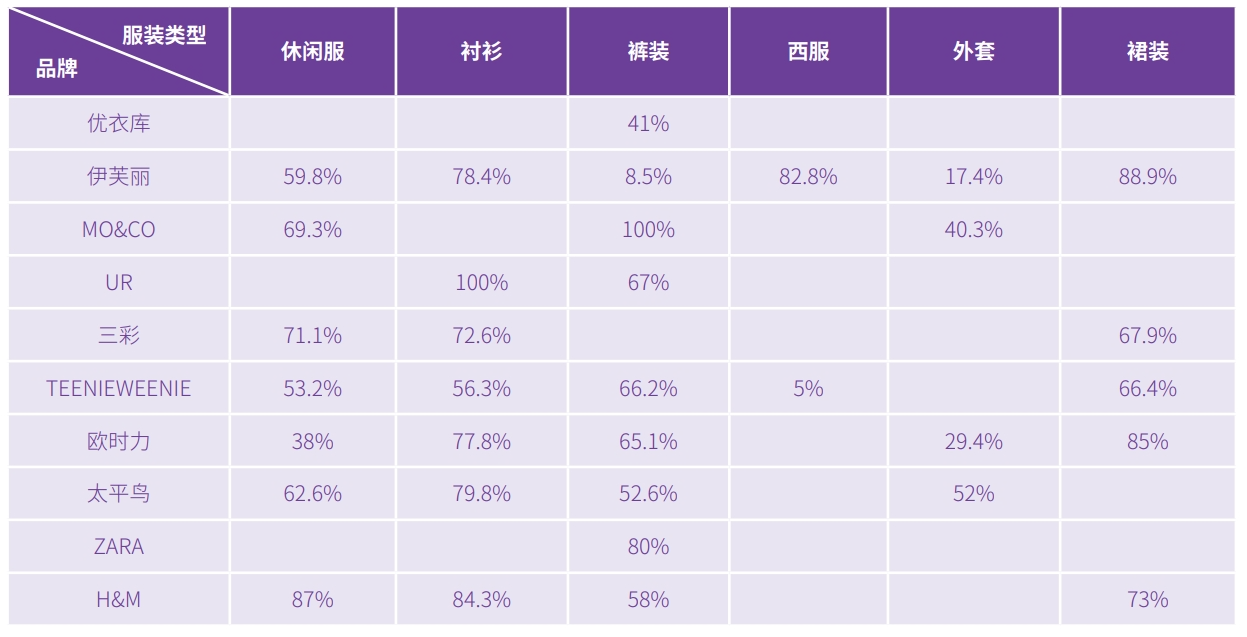

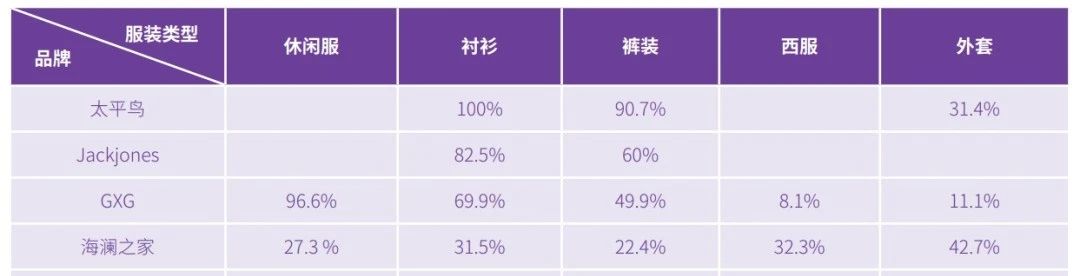

According to the 2024 Lyocell Fiber Application Trend Report published by the China Chemical Fiber Industry Association, based on the "2023 Tmall Clothing Brand Double 11 Official Sales Ranking", selected brands for women's, men's, and children's clothing were chosen, and the content of lyocell fiber (here refers to a general term, not all are zero carbon fiber) in clothing from these brands in Tmall flagship stores was surveyed.

Source: 2024 lyocell fiber application trend report

The statistical results show that well-known brands on the list have more or less used lyocell fiber, with product types mainly concentrated in shirts, skirts, and casual home wear. Among them, brands such as Eifini, HLA, TEENIEWEENIE, GXG, Ochirly, Peacebird, H&M, and others have incorporated lyocell fiber in various proportions into their products.

Meanwhile, the popularity of zero carbon materials has indirectly promoted the development of zero carbon clothing. This year, the sustainable brand ZOZORIKA launched the world's first carbon-neutral pet clothing, Jelly Fish, which uses carbon-neutral yarn materials from the sustainable and environmentally friendly yarn enterprise UPW in its raw materials.

The carbon neutral certificate for ZOZORIKA's pet clothing

ZOZORIKA teamed up with Carbon Newture, utilizing the Carbon Newture digital carbon management platform, to conduct a carbon footprint assessment for the Jelly Fish pet clothing throughout its entire lifecycle, from "cradle to grave." Through carbon offsetting, they achieved carbon neutrality for the product and obtained authoritative certification.

The textile and apparel industry has a long industrial chain and complex production processes, with significant differences in processing methods and involvement of various materials, which increases the difficulty of calculating the carbon footprint of products. To accurately understand the reduction in carbon footprint due to the use of low-carbon or zero-carbon raw materials, it is necessary to rely on third-party dual carbon service companies that can provide digital carbon management platforms for precise quantification. Accurate data and authoritative certificates are required to prove the efforts made by companies in the direction of green and low-carbon initiatives.

Reference:

[1]莱赛尔纤维词条,百度百科